Inspection Bodies

About

Inspection is the examination of a product design, product service or process/plant. It also involves determining its conformity, either against specific requirements or on the basis of professional judgment. This broad definition thus covers a wide variety of inspection activities.

The Scheme

The Accreditation Scheme for Inspection Bodies provides official recognition of the integrity and reliability of an inspection body’s services. Achieving effective inspection is important in maintaining the safety of plant machinery, equipment, structures and systems in operation.

Launched in April 2011, the Accreditation Scheme for Inspection Bodies aims to upgrade the standard of inspection activities to support sound decision-making with regard to safety, health, performance and reliability.

Accreditation is offered to all inspection services – from in-house to independent inspection bodies. Some areas of inspection include pressure vessels, lifting equipment, motor vehicle, structural steelwork and site investigation.

Accreditation allows an inspection body to benchmark its work practices against the world’s best practices.

Accreditation Criteria

Inspection bodies are accredited based on the international standard, ISO/IEC 17020 - “General Requirement for the Operation of Various Types of Bodies Performing Inspection”. The Assessment Team comprises a Lead Assessor(s) and Technical Assessor(s). Upon accreditation, the organisation is officially deemed capable of meeting standards of quality, performance, technical competence and professional judgment.

Aside from the international standard, there are also specific technical notes that the inspection body has to comply with, which depends on the area of inspection.

Accreditation for inspection bodies is granted for a specific scope of inspection activities; only the accredited inspection activities can bear the accreditation mark, thus increasing confidence in users.

Benefits

Accreditation will:

-

Gain new business: As more specifiers and users are stipulating the use of accredited services, a SAC-accredited inspection body will help you to garner acceptance of your products and services. This results in better competitiveness and market access.

-

Reduce cost: Properly inspected products and services are more cost-effective, thus reducing downtime and avoiding any unnecessary cost for rework or re-inspection.

-

Lower risk: With the technical proficiency of a SAC-accredited inspection body, your products are assured of their reliability and competence. This mitigates claims and unnecessary recall of your products.

Aside from attaining a systematic and well-designed quality system, accredited organisations also stand to gain from the Mutual Recognition Arrangements (MRAs) that SAC has signed. This allows them access to international markets.

Process

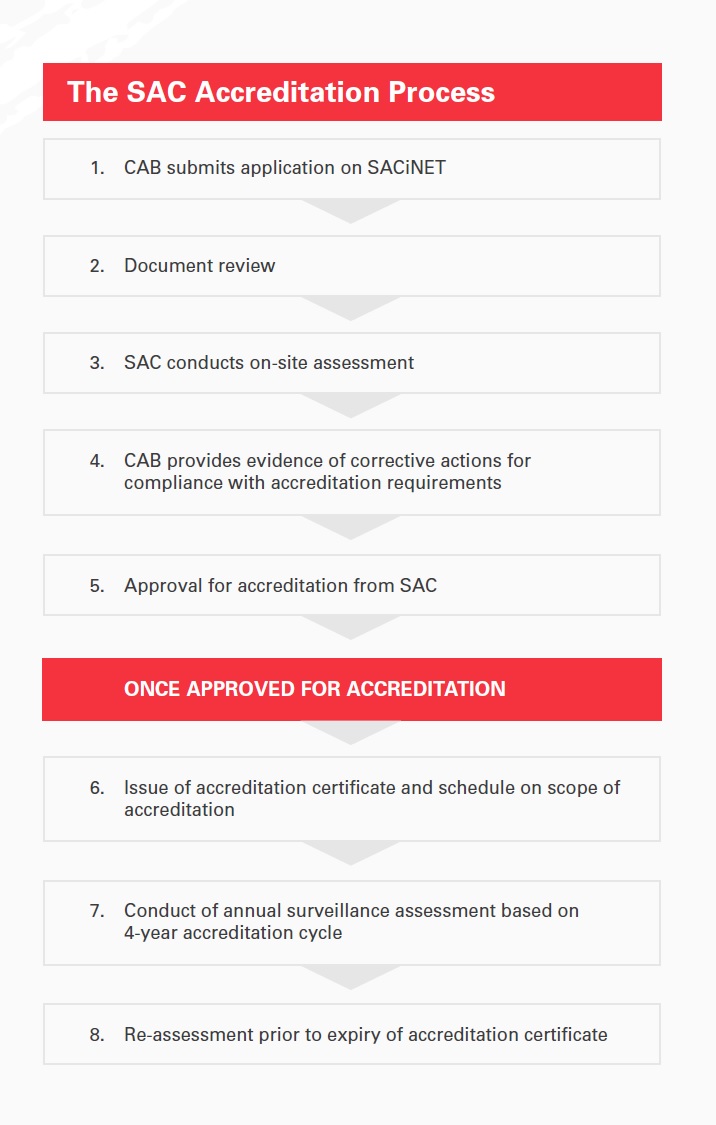

Upon receiving the application for accreditation, the secretariat will send a quotation to the inspection body and arrange for a preliminary assessment. This assessment is conducted by a team that comprises SAC staff and a technical assessor, who is from the technical community, either within the country or overseas. When the inspection body has demonstrated compliance with our requirements, it will be recommended for accreditation. Once approved, SAC will grant a certificate of accreditation. The detailed description of the type of assessment is stipulated in IB-01, Accreditation Process.

The schematic diagram of the accreditation process is described below:

Upon fulfilling the basic requirements, the CAB can apply online through the SACINET website.